PLC-ANALYZER pro 6

Características destacadas

- Diagnostico de fallas

- Grabación a largo plazo

- Documentación del sistema

- Instalación / Servicio

- Mantenimiento predictivo

- Monitoreo de condición

- Optimización del tiempo de ciclo

Descripción

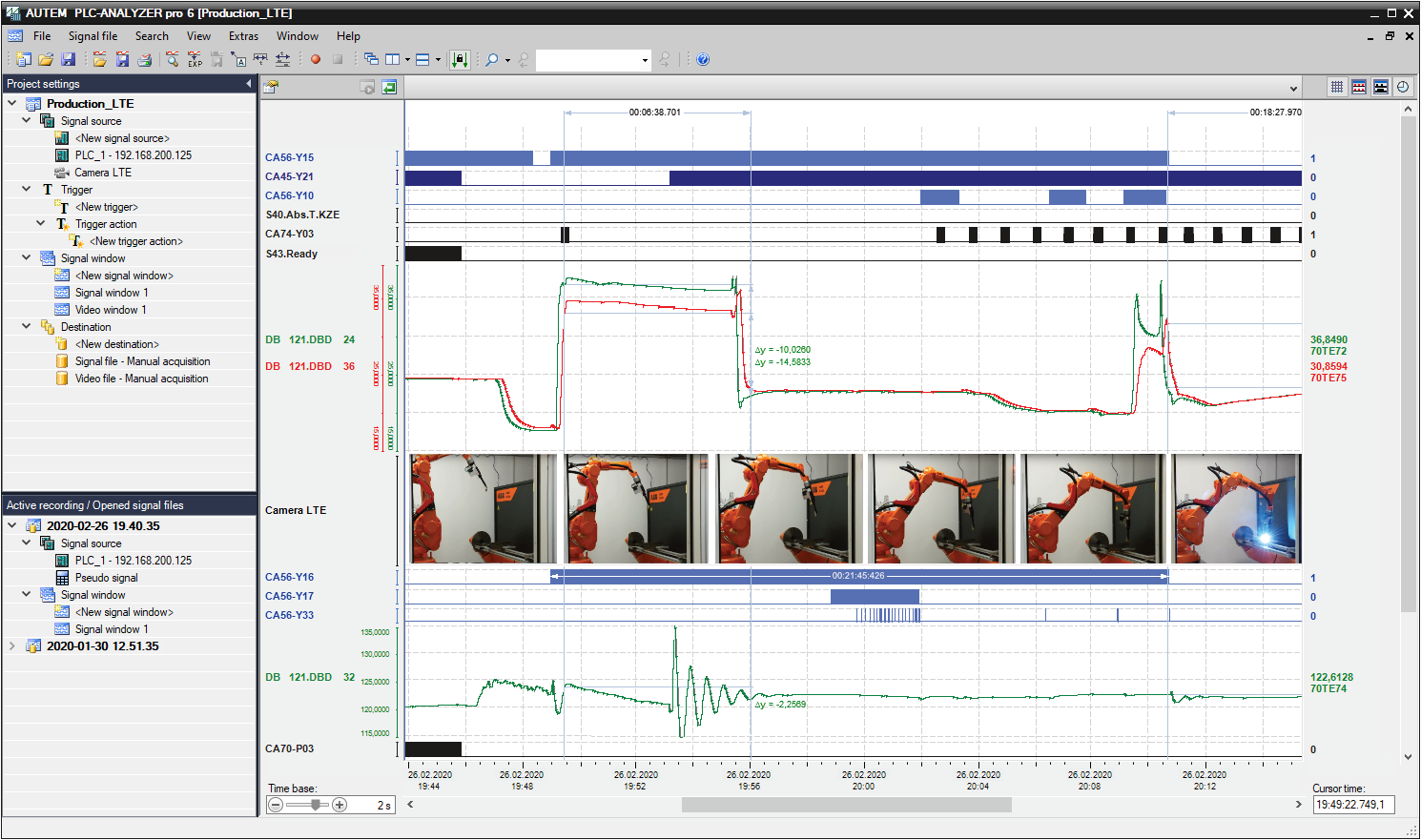

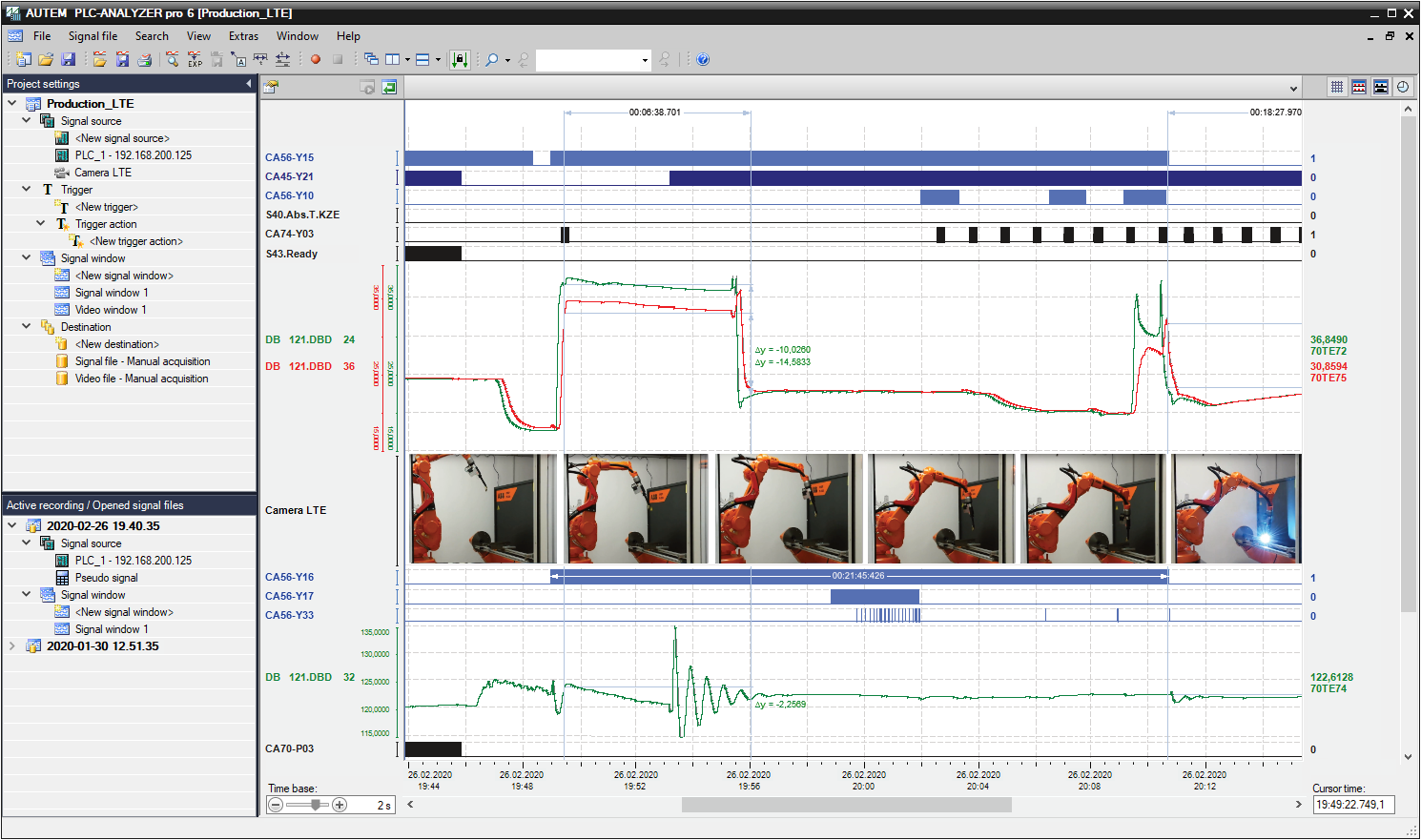

PLC-ANALYZER pro 6 by AUTEM is a software system for logic analysis and recording of measured values in PLC-controlled facilities. Acquisition, representation and evaluation of PLC signals such as input, output, flags, timer, counter, data of data blocks, is now very easy. In addition, video data can also be recorded synchronously with the PLC process data (Videotrack module).

Fields of application- Failure diagnosis

- Detecting and localizing of sporadic errors

- Cycle time optimization

- Long-term recording of measured values

- System documentation, TPM/OEE, EU-Machinery directive

- Condition monitoring / Predictive maintenance

- Warrenty: incorruptible clarification

- Quality assurance

- Installation, development, maintenance

Live display allows the observation of the signal waveform in real time. Analysis and evaluation can already be carried out at the time of recording. In addition to long-term recording, trigger conditions can be specified for the acquisition of particular events. This allows rarely occurring sporadic errors to be specifically recorded for later analysis

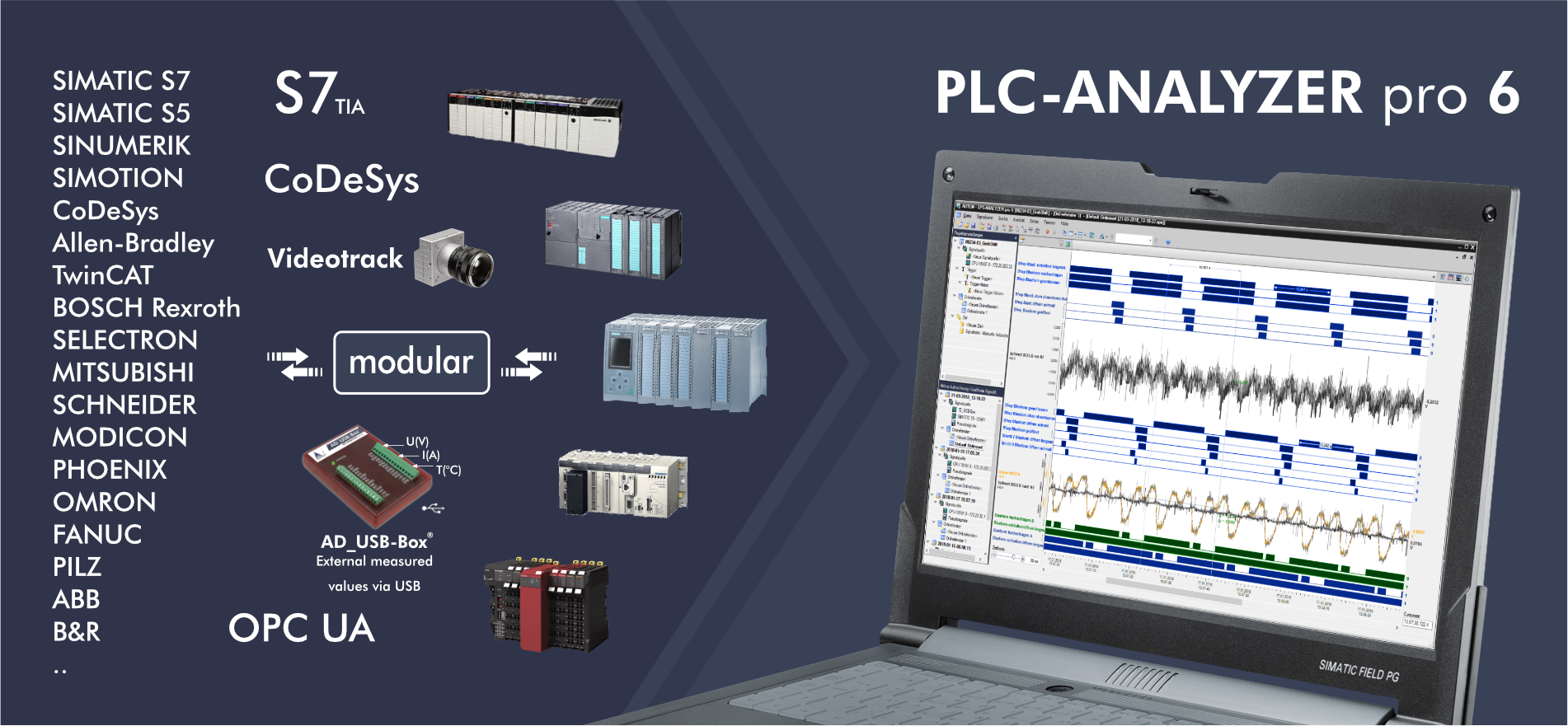

PLC-ANALYZER pro 6 has the decisive advantage of recording process data via standardized PLC interfaces. For example, for SIMATIC S7 signals can be acquired using MPI/PPI, PROFIBUS or TCP/IP PROFINET. All CoDeSys communication paths and many other PLC connections of various manufacturers are supported.

A programming device or notebook, that is connected for the purpose of programming the PLC, can be used for recoding process data without modification. By means of high-performance PLC drivers (in-house development) the PLC-ANALYZER pro 6 achieves sampling rates, which would not be possible with a OPC-UA-based solution.

The tiresome process of hooking up monitoring cables is now a thing of the past. Cycle-precise recording is attractive because of the complete acquisition of measured values in each PLC cycle. Up to 16 million variables from 250 signal sources can be recorded simultaneously.

PLC-ANALYZER pro 6 simplifies the signal selection by using symbol files or projects of the PLC programming software. Loading a TIA / STEP7 project makes all settings and variables immediately available

The Videotrack module provides additional visual support for troubleshooting by video recording synchronous to the PLC signal acquisition. This is a great help for error analysis on machines and systems, since the mechanical situation can be viewed synchronously with the process data using the video frame.

The Virtual HMI module helps to clarify plant accidents involving human operators. The subsequent HMI visualization from recorded process data makes it easier to detect possible operating errors. The HMI visualization can also take place live during the recording.

By using the measurement interface AD_USB-Box® external voltage and current signals, which are not available in the PLC, can also be recorded. This is also very helpful in case of the demand of capturing I/Os from PLCs, for which a specific PLC driver is not available.

For a direct integration of PLC-ANALYZER pro 6 in the facility, AUTEM offers the ultra compact BLACKBOX 3. This mini industrial PC allows autarkic process data archiving over long periods of time. Thanks to numerous remote connection possibilities – 4G LTE-Modem, WAN, LAN – the BLACKBOX 3 is ideally suitable for machine remote service.

PLC-ANALYZER pro 6 is an indispensable tool for PLC software development, construction, installation, technical maintenance and training.

AUTEM offers a customer-friendly licensing concept (incl. maintenance & support) with primary and additional licenses for the equipment of one or more workstations. For prices and part-numbers please refer to our current price list.

PLC Analyzer drivers

| PLC driver | Interface | Remark | Manual |

|---|---|---|---|

| Siemens SIMATIC S7 / TIA | Ethernet TCP/IP, PROFINET | TIA-Portal compatible, cycle precise* (also for SIMATIC C7, M7, S7-PLCSIM, SINUMERIK S7, VIPA S7, Insevis S7, Yaskawa SLIO/300S+) | |

| Siemens SIMATIC S7 / TIA | MPI/PPI, PROFIBUS | TIA-Portal compatible, cycle precise* (also for SIMATIC C7, M7, S7-PLCSIM, SINUMERIK S7, VIPA S7, Insevis S7, Yaskawa SLIO/300S+) | |

| Siemens SIMATIC S5 / SINUMERIK | programming interface, Ethernet TCP/IP | cycle precise* | |

| Siemens LOGO! | programming interface, Ethernet TCP/IP | ||

| Siemens SIMOTION C/P/D | MPI, PROFIBUS, Ethernet TCP/IP | ||

| CoDeSys | Ethernet TCP/IP | For all CoDeSys based PLCs, e.g. ABB, Berghoff, Bosch Rexroth, Eaton, Elau, Festo, Hitachi, KEBA, Lenze, Schneider, Hans Turck, WAGO etc. For BECKHOFF please use the specific BECKHOFF TwinCAT driver! | |

| BECKHOFF TwinCAT | Recording TwinCAT variables | ||

| OPC UA | Recording data from OPC UA servers | For all OPC UA compatible PLCs/devices/sensors. If available, the use of a specific PLC driver is recommended for better performance. | |

| B&R | Serial, Ethernet TCP/IP | ||

| PILZ PSS / PNOZ | programming interface | ||

| PILZ PSS / PNOZ | Ethernet TCP/IP | ||

| Allen-Bradley ControlLogix / PLC / SLC | DF1 / DH+/ DH-485 | ||

| Allen-Bradley Compact/ControlLogix / PLC / SLC | Ethernet TCP/IP | ||

| PHOENIX | Ethernet TCP/IP | cycle precise* | |

| BOSCH CL | programming interface (BUEP19E) | ||

| GE FanucSerie 90 / VersaMax / Nano / Micro | programming interface (SNP) | ||

| GE Fanuc CNC / PMC | HSSB / Ethernet TCP/IP | ||

| Fanuc R-30i / R-J3i | Ethernet TCP/IP | ||

| OMRON C / CV / CS1 / NJ / NX / NY / CJ2 | programming interface (Host Link) / Ethernet TCP/IP | ||

| MITSUBISHI MELSEC Q / L / A / FX | programming interface | ||

| MITSUBISHI MELSEC Q / L / A / FX | Ethernet TCP/IP | ||

| Schneider Modicon TSX Quantum / Momentum | Compact - Modbus I / Modbus Plus | value="Download"> | |

| Schneider Modicon TSX Quantum / Momentum | Compact / M - Modbus TCP/IP | value="Download"> | |

| Schneider Modicon TSX Premium / Atrium |

Micro / Nano - Uni-Telway / TCP/IP | ||

| Schneider AEG TSX A250 / A120 / Micro | programming interface (KS) | ||

| Selectron | Ethernet TCP/IP | ||

| Jetter JetControl / Delta / Nano | Serial / Jetway / PC-PPLC / Ethernet TCP/IP | ||

| HITACHI H / EH-150 / Micro-EH | programming interface / Ethernet TCP/IP |

||

| Videotrack modul | LAN/WiFi (IP/GigE Vision) / USB | Software connection for IP / GigE Vision / USB cameras | |

| Virtual HMI module | All AUTEM (PLC-)Drivers | Improved analysis of operating sequences through subsequent HMI visualization from recorded process data. | |

| AD_USB-Box® | USB | Recording of external voltage and current signals |

Especificaciones Tecnicas

| Pure software solution: No special additional hardware required |

| No need to make any changes in the PLC program |

| Data recording via existing connection to the PLC (Ethernet TCP/IP, serial, Fieldbus, …) |

| High-performance sampling by specific PLC drivers |

| Recording of input, output, flag, timer, counter, peripheral, data of data blocks and other PLC variables |

| Optimized data blocks (S7 1200/1500): Variables direct readable |

| bit-, byte-, word-, double- or quad-word format |

| Pseudo signals: generating of virtual signals by [complex] calculation from recorded signals |

| Simultaneous acquisition from several PLC systems / also different manufactures (e.g. SIMATIC S7 + CoDeSys) |

| Up to 250 signal sources / 16 million variables |

| Videotrack (optional): Camera recording synchronous with PLC signal capturing |

| Cycle precise recording for different PLC systems |

| Supports PC based PLC (e.g. Beckhoff TwinCAT) and PLC simulators (e.g. S7-PLCSIM) |

| Recording modes: continuous recording, trigger-, time-controlled |

| Enable/Disable of addresses and triggers during recording |

| Real-time online display of signals |

| Comfortable PLC signal selection for online window by drag & drop |

| Analysis of signal data possible while recording |

| Highly accurate display of signals with short-term fluctuations of measured values („spikes“) |

| Comfortable trigger definition by drag & drop |

| Trigger on binary and register values with AND/OR/XOR/RS and cascading |

| Pre- and post-trigger time freely selectable |

| Extensive trigger actions: Notification (E-Mail, SMS, acoustic announcement, pop-up-window), any PC-commands |

| Comparing of signal files |

| Search function: search for trigger, edge, bit pattern, register values, time and notes – even across several signal files |

| Time difference measurement and automatic bit measurement |

| Relative and absolute data-time |

| Flexible signal scaling and normalization – e.g. conversion in physical units or min-max-ajustment of measured value |

| Number format: decimal, hexadecimal, binary, ASCII, REAL (floating point), S5-TIME, TIME, DATE, DATETIME |

| Use of symbolic address names and comments from PLC programming software – e.g. TIA-Portal |

| Projects for pre-configuring and automating data acquisition runs |

| Extreme robust and compact file format |

| Multiple data targets at the same time: e.g. simultaneous writing of signal file and CSV file |

| Export of signal files: PDF, CSV, Excel, HTML, graphic formats |

| Import of CSV files: visualisation of other measure values |

| Printing of signal files and measurement configuration |

| Multilingual user interface: German / English |

| System requirements: PC with 1.2 GHz, 2 GB RAM, 2 GB available hard-disk space, Microsoft® Windows 7/8/10 (32/64-Bit) |

| AD_USB-Box® (optional): Recording of external voltage and current with external box connected via USB |

| Videotrack module (optional): The Videotrack module enables video recording time-synchronous to PLC signal capturing. |

| BLACKBOX 3 (optional): Ultra-compact industrial PC for control cabinet; long-term process data recording, monitoring, remote maintenance |

| Referencia | Descripcion |

|---|---|

| PLC Analyzer PRO 6 | PLC Analyzer PRO 6 |